Dynamic, synergetic processes to improve resource efficiencies, valorising by-products and waste, and binding CO2

Gefn's technology for production and application of renewable specialty chemicals, solvents and intermediates offers dynamic and synergetic processes, which improve resource efficiencies and eliminate fossil-based feedstocks by localised valorisation of by-products and waste from processing of oleo-feedstocks and by utilisation of climate-neutral CO2.

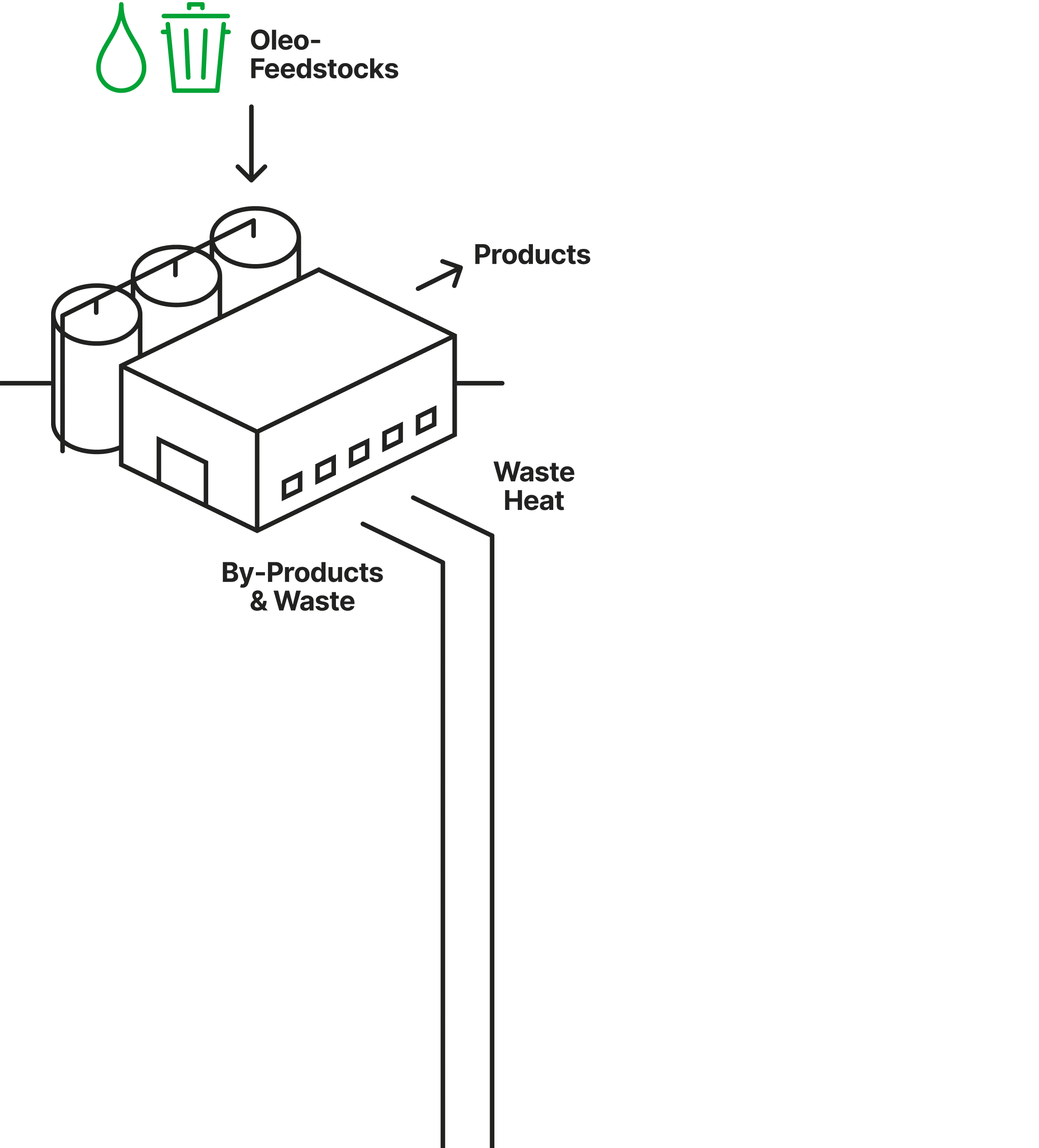

Utilisation of by-products and waste from oleo-feedstock processing

The oleochemical, biodiesel and omega-3 industries, and other oleo-feedstock processing, often generate considerable amounts of low value by-products and waste such as glycerol, fatty acids and triglycerides.

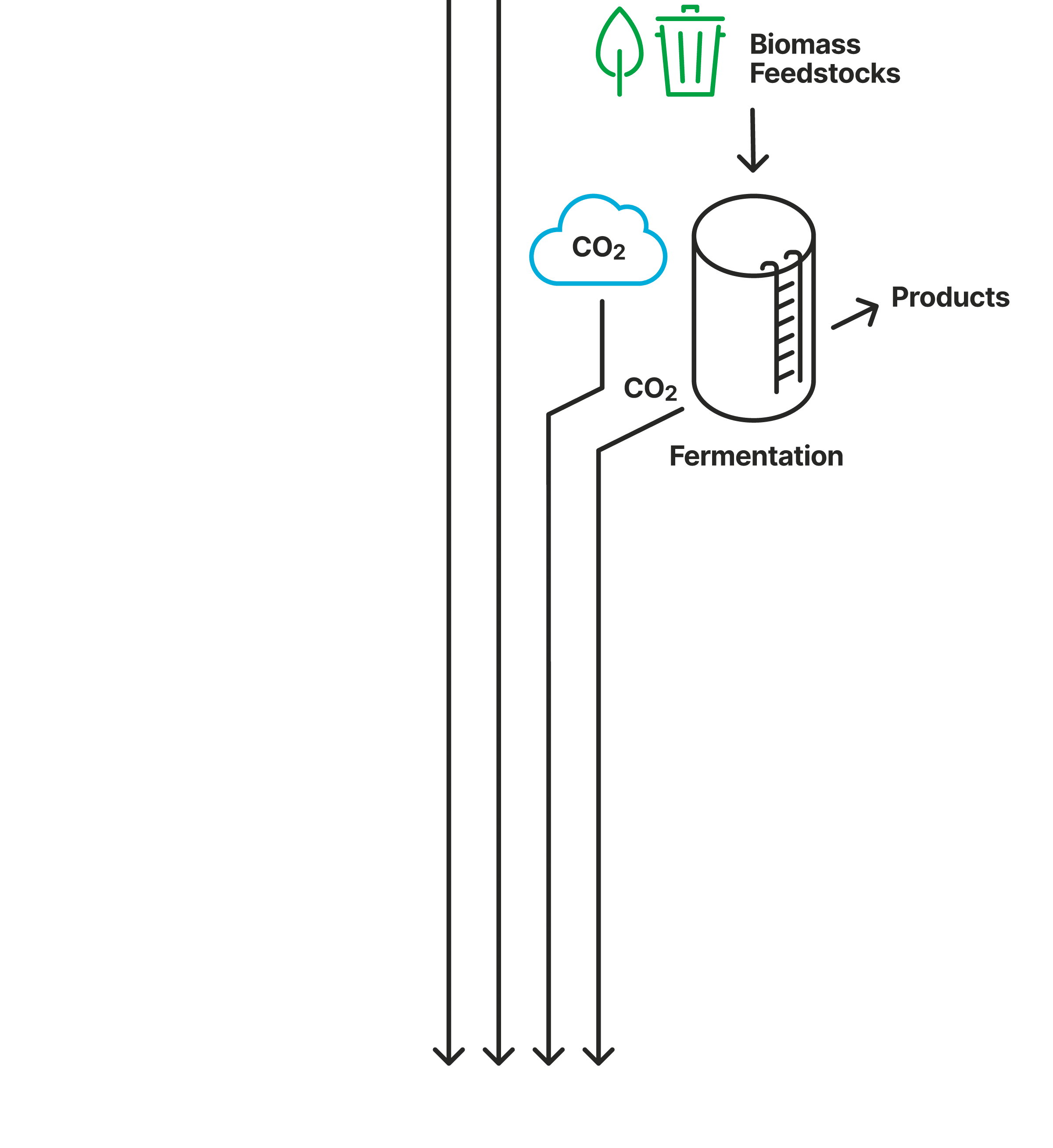

Climate-neutral CO2 as a raw material

Sourcing of climate-neutral CO2 by direct air capture (DAC) and from fermentation and digestion of biomass, such as production of bioethanol and biomethane, constitute important alternative sources of carbon which can valorised in oleo-feedstock conversions.

Dynamic, economical and localised production of renewable, sustainable chemicals

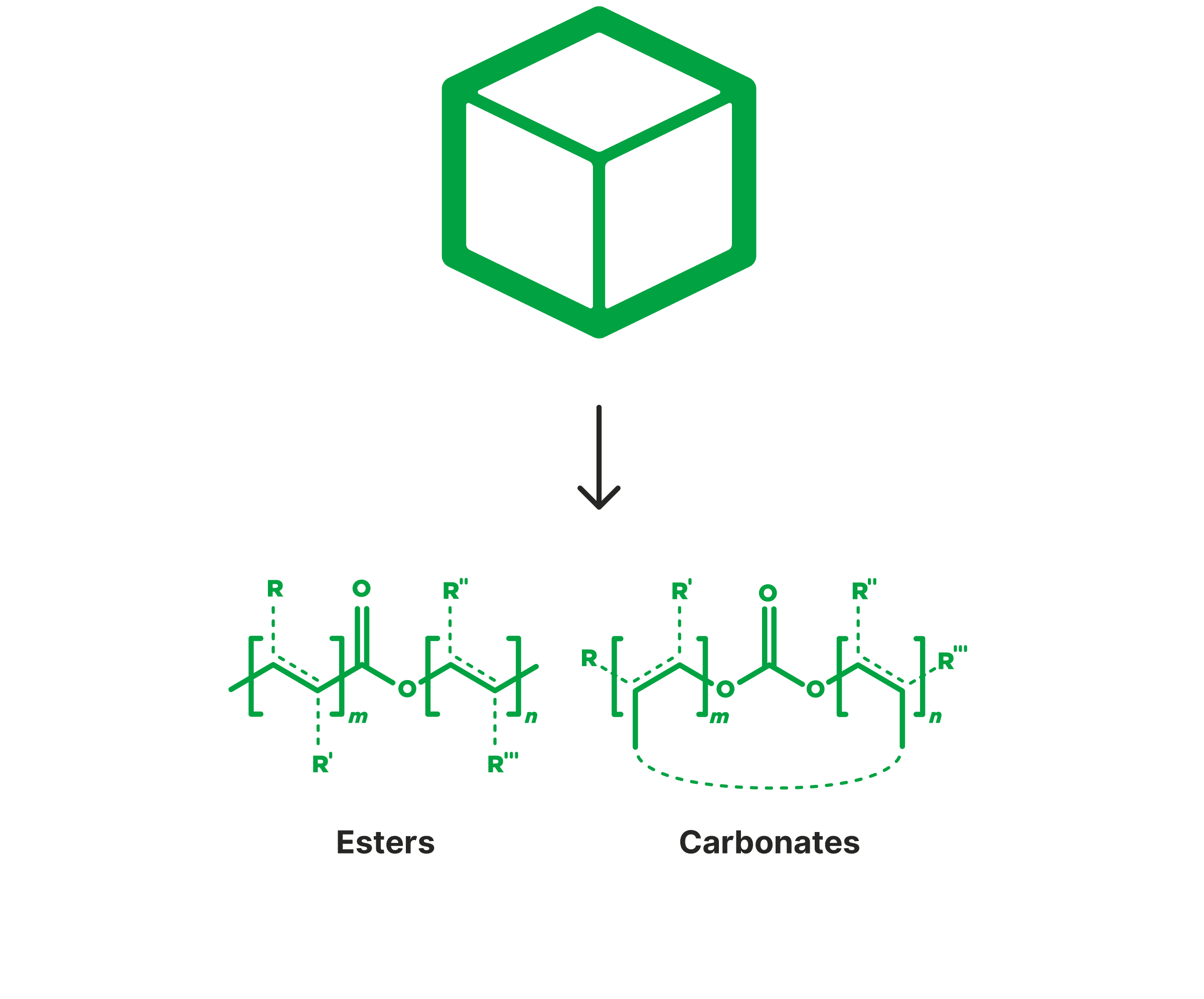

Gefn’s process intensification-based technology enables dynamic, economical and localised production of green chemicals by conversion of glycerol, fatty acids and triglycerides through reactions with alcohols, carboxylic acids and climate-neutral CO2 into valuable carbonates and esters, subsequently used as specialty chemicals, solvents and intermediates.

Boost your factory’s resource efficiencies and achieve a carbon-negative footprint

Gefn’s plug-on processes synergistically improve resource efficiencies and production economics in oleo-feedstock processing plants. The associated utilisation of climate-neutral CO2 enables carbon-negative products and even an overall carbon-negative footprint.

Production of green industrial and consumer products

The obtained carbonates and esters have a broad range of applications in cleaning products, personal care products, cosmetics, pharmaceuticals, paints, fuel additives, batteries, nutritional products and more. They can also serve as intermediates and be processed further into existing specialty and fine chemicals as well as for synthesising new types of materials.

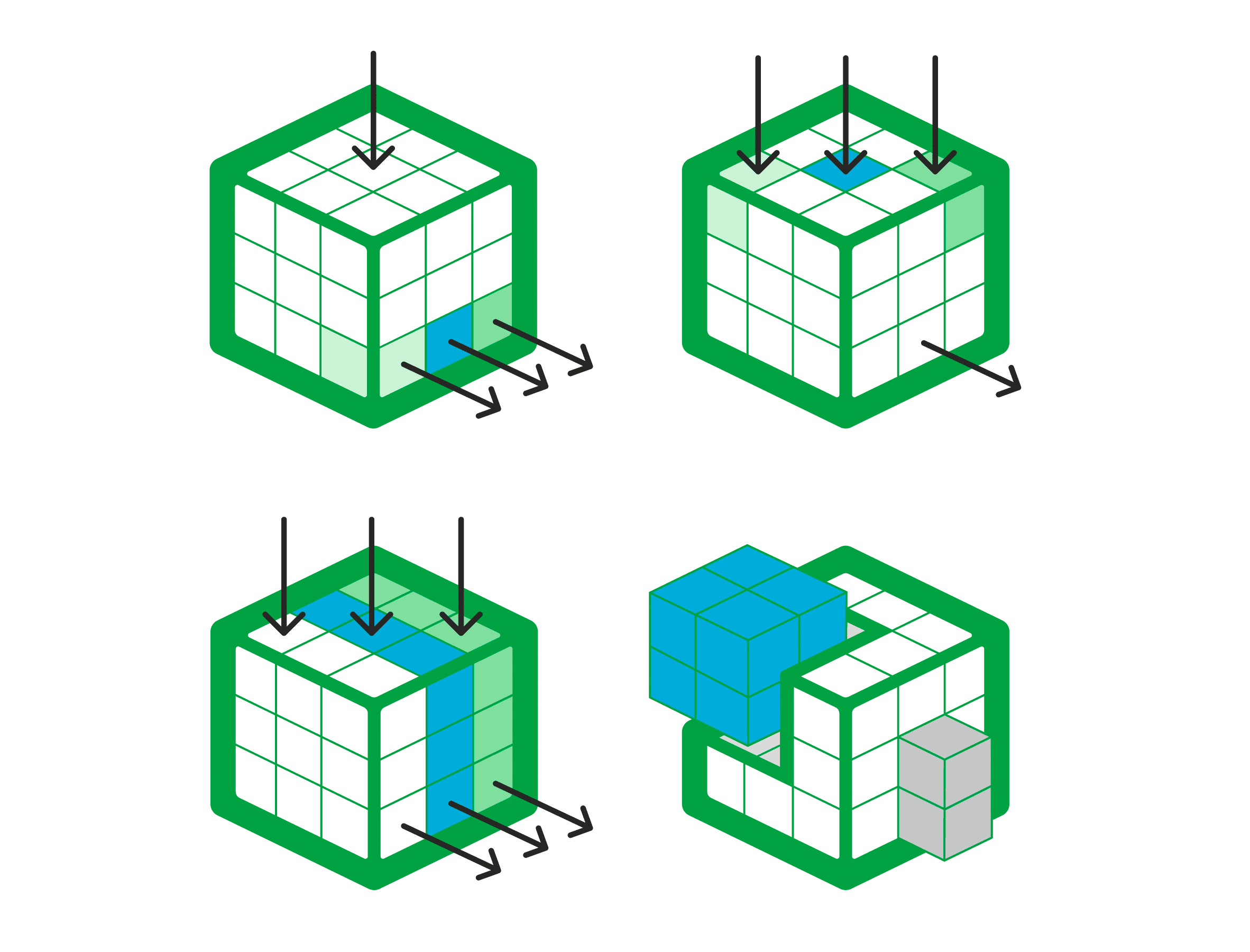

Flexible process technology

Gefn’s process intensification-based technology is applied as complete and modular plug-on processes or as separate equipment. The modularity minimises downtime during integration and enables modifications and relocation.

The dynamic nature of Gefn’s processes and equipment allows flexibility in raw materials and products for optimisation of production costs and revenues. The technology enables a faster respond time to meet the needs of customers and the market.

Efficient replacement of fossil-based specialty chemicals and solvents

The green chemicals resulting from Gefn’s technology are suitable and efficient for replacing fossil-based specialty chemicals and solvents in a wide range of industrial and consumer products. Gefn develops optimised formulations to maximise performances and minimise costs and environmental effects of the end products.

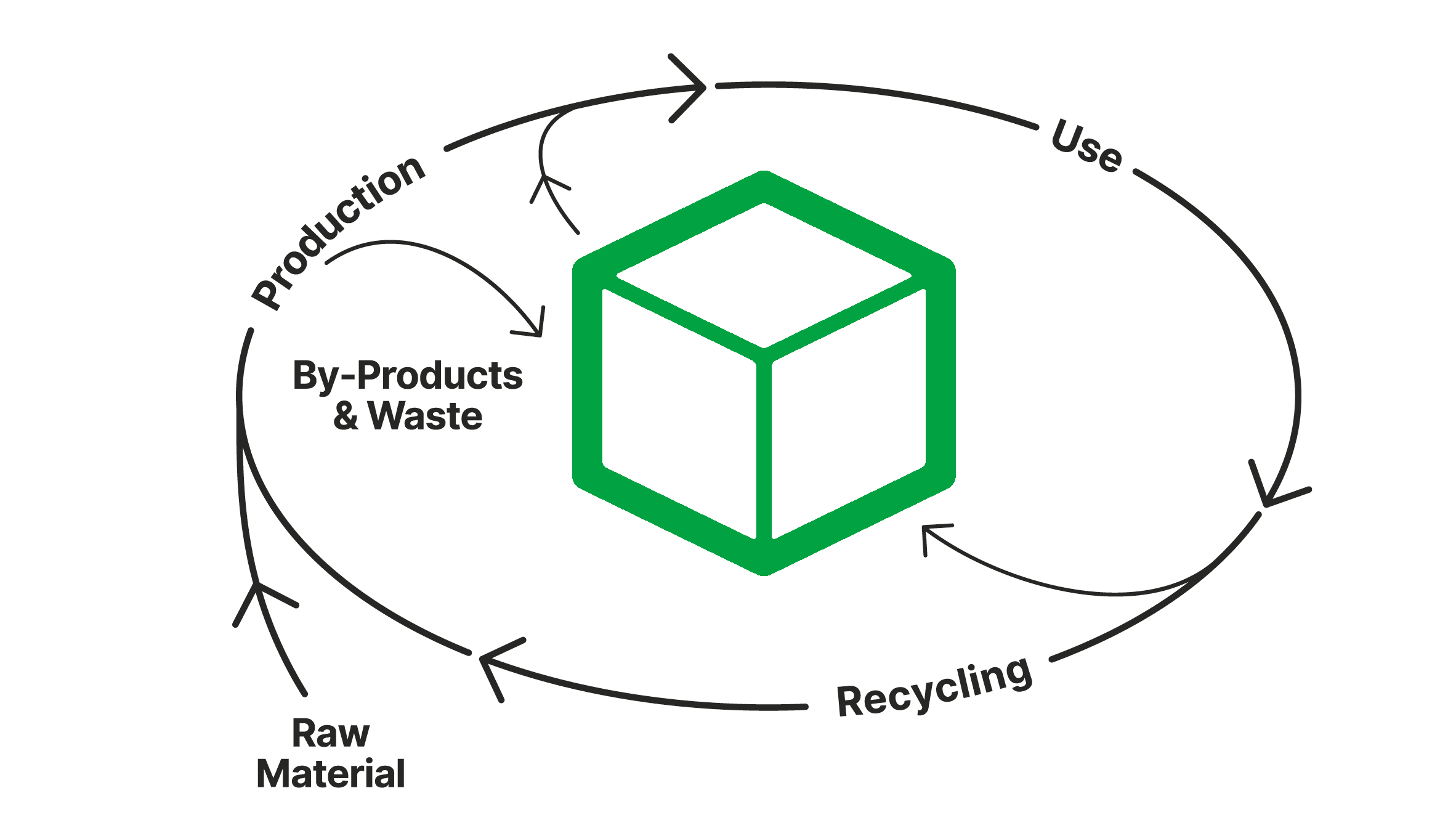

Tomorrow’s chemical industry needs to be Circular Economy-ready

Gefn’s innovations will enable tomorrow’s chemical industry to profitably utilise “above ground carbon” in the form of by-products, waste and climate-neutral CO2 with ever less reliance on fossil-based hydrocarbons and virgin oleo-feedstocks. Gefn is constantly developing its technology towards yielding greener chemicals by increasing the proportion of climate-neutral CO2 in the overall feedstock mix.

Partners

Gefn has a broad range of strategic supply partners to support its R&D, engineering and commercialisation activities and downstream partners provided with technical services within Gefn’s core competences.

Become a partner

What is Gefn?

Gefn is an innovative Icelandic chemical engineering company that develops and commercialises innovative solutions for the production and application of green chemicals and provides technical services in related fields. Gefn’s technology enables a profitable compliance with the emerging Circular Economy.